Tungsten Carbide Cutting Blades: The Environmental Impact You Should Know

Tungsten Carbide Cutting Blades: The Environmental Impact You Should Know

Introduction to Tungsten Carbide Cutting Blades and Their Industry Significance

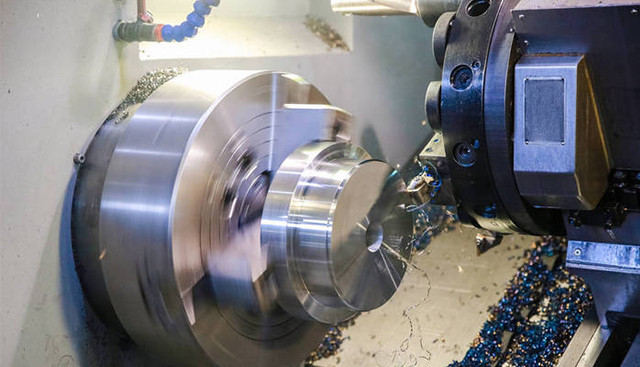

Tungsten carbide cutting blades are renowned for their exceptional hardness, durability, and cutting efficiency across diverse industrial applications. From metal fabrication, woodworking, and stone cutting to precision machining, tungsten carbide blades are indispensable for their ability to perform under extreme conditions. As industry leaders, Dongcheng emphasizes not only product excellence but also the environmental responsibilities associated with manufacturing and utilizing these advanced tools.

Understanding Tungsten Carbide: Composition and Manufacturing Processes

Tungsten carbide is a composite material formed by blending tungsten powder with carbon, creating a compound that exhibits remarkable wear resistance and toughness. The manufacturing process involves several energy-intensive steps:

Mining of Tungsten Ore: Extracted primarily from wolframite or scheelite minerals, tungsten ore mining can cause significant ecological disturbances, including habitat destruction, water contamination, and high energy consumption.

Refinement and Powder Production: The ore undergoes crushing, milling, and chemical processing to produce tungsten powder, which requires substantial chemical inputs and energy.

Sintering and Tool Formation: The powdered tungsten carbide is mixed with metal binders (like cobalt), pressed into molds, and sintered at high temperatures, consuming vast amounts of energy and generating greenhouse gases.

Environmental considerations during these processes include resource depletion, chemical waste management, and high carbon emissions, all of which impact ecological sustainability.

Environmental Impact of Tungsten Carbide Cutting Blade Production

Resource Extraction and Ecological Footprint

The initial extraction of tungsten contributes to deforestation, soil erosion, and water pollution. Mining operations often involve open-pit techniques that disturb large land areas, leading to biodiversity loss. Additionally, the chemical processes used to refine tungsten ore may release heavy metals and toxic substances into surrounding ecosystems.

Energy Consumption and Carbon Emissions

The manufacturing stages—particularly sintering—are highly energy-dependent, often relying on fossil fuels. This results in a significant carbon footprint, contributing to climate change. Dongcheng actively seeks to implement energy-efficient manufacturing practices and renewable energy sources to mitigate these impacts.

Chemical Waste and Pollution

Chemical reagents used during ore processing and powder production pose risks of chemical spills, airborne toxins, and water contamination. Proper waste management protocols are crucial to prevent environmental degradation, and continuous innovation is necessary to reduce chemical reliance.

Environmental Challenges During Usage of Tungsten Carbide Cutting Blades

Durability and Extended Service Life

One of the environmental advantages of tungsten carbide blades is their long service life. Their durability translates into fewer replacements, reducing waste and resource consumption over time. Dongcheng designs blades with optimized toughness to maximize lifespan, thus decreasing the ecological footprint associated with manufacturing and disposal.

Energy Efficiency in Cutting Operations

High-performance tungsten carbide blades require less energy during cutting tasks due to their efficiency. This results in lower energy consumption in industrial processes, indirectly benefiting the environment by reducing greenhouse gas emissions.

Potential for Wear and Microplastic Generation

Despite their durability, tungsten carbide blades will eventually wear out. The debris generated during grinding or disposal can contain micro-particles of tungsten carbide, which are challenging to manage environmentally. These particles can persist in ecosystems, posing risks to aquatic life and soil health.

Disposal and Recycling of Tungsten Carbide Blades: Environmental Concerns

Challenges in Disposal

Disposing of tungsten carbide blades can pose environmental hazards. If improperly discarded in landfills, they can leach heavy metals such as cobalt and tungsten into soil and groundwater. Incineration is also problematic, as it may release toxic fumes.

Recycling and Reuse Initiatives

Recycling tungsten carbide is feasible and increasingly adopted within the industry. Recycling processes involve:

Crushing and milling to recover tungsten and cobalt powders.

Chemical and thermal treatments to purify recovered materials.

Recasting into new blades or industrial components.

Dongcheng invests in sustainable recycling initiatives, encouraging customers to participate in take-back programs and promote circular economy practices.

Environmental Benefits of Recycling

Recycling tungsten carbide significantly reduces resource extraction pressure, minimizes energy consumption, and decreases carbon emissions associated with primary manufacturing. It also reduces waste in landfills and limits the release of toxic substances.

Innovative Eco-Friendly Alternatives and Future Trends

Development of Eco-Conscious Materials

Research is ongoing to develop biodegradable or less toxic cutting materials. Although tungsten carbide remains the industry standard, innovations such as ceramic composites or diamond-coated blades are emerging as sustainable options.

Green Manufacturing Practices

Leading manufacturers like Dongcheng are adopting green manufacturing techniques, including:

Energy-efficient sintering technologies

Use of renewable energy sources

Chemical-free or less toxic processing methods

Waste heat recovery systems

Regulatory and Certification Standards

Global standards increasingly mandate environmental impact assessments and sustainable manufacturing certifications. Compliance ensures that tungsten carbide blades are produced with minimal ecological footprint, aligning industry growth with environmental stewardship.

The Role of Industry Leaders in Promoting Sustainability

As a trusted manufacturer, Dongcheng recognizes its responsibility to lead by example in reducing environmental impacts. Our commitments include:

Investing in clean energy and efficient manufacturing equipment

Developing recyclable and eco-friendly product lines

Promoting sustainable sourcing of raw materials

Educating customers on proper disposal and recycling practices

Conclusion: Navigating the Environmental Impact of Tungsten Carbide Cutting Blades

While tungsten carbide cutting blades offer unparalleled performance and longevity, their environmental footprint—from resource extraction to disposal—requires careful management. Industry stakeholders, including Dongcheng, are committed to advancing sustainable practices through innovation, recycling, and responsible sourcing.

By understanding these impacts and actively pursuing eco-conscious solutions, we can ensure that the benefits of tungsten carbide cutting technology are harnessed without compromising our planet's health. Transitioning toward greener manufacturing and usage practices not only aligns with global environmental goals but also sustains the industry’s future growth.

Contact Dongcheng today to learn more about our eco-friendly tungsten carbide cutting blades and our commitment to sustainable manufacturing practices. Together, we can forge a more sustainable future for industrial cutting solutions.