Step-by-Step: How to Use Tungsten Carbide Cutting Blades Like a Pro

Step-by-Step: How to Use Tungsten Carbide Cutting Blades Like a Pro

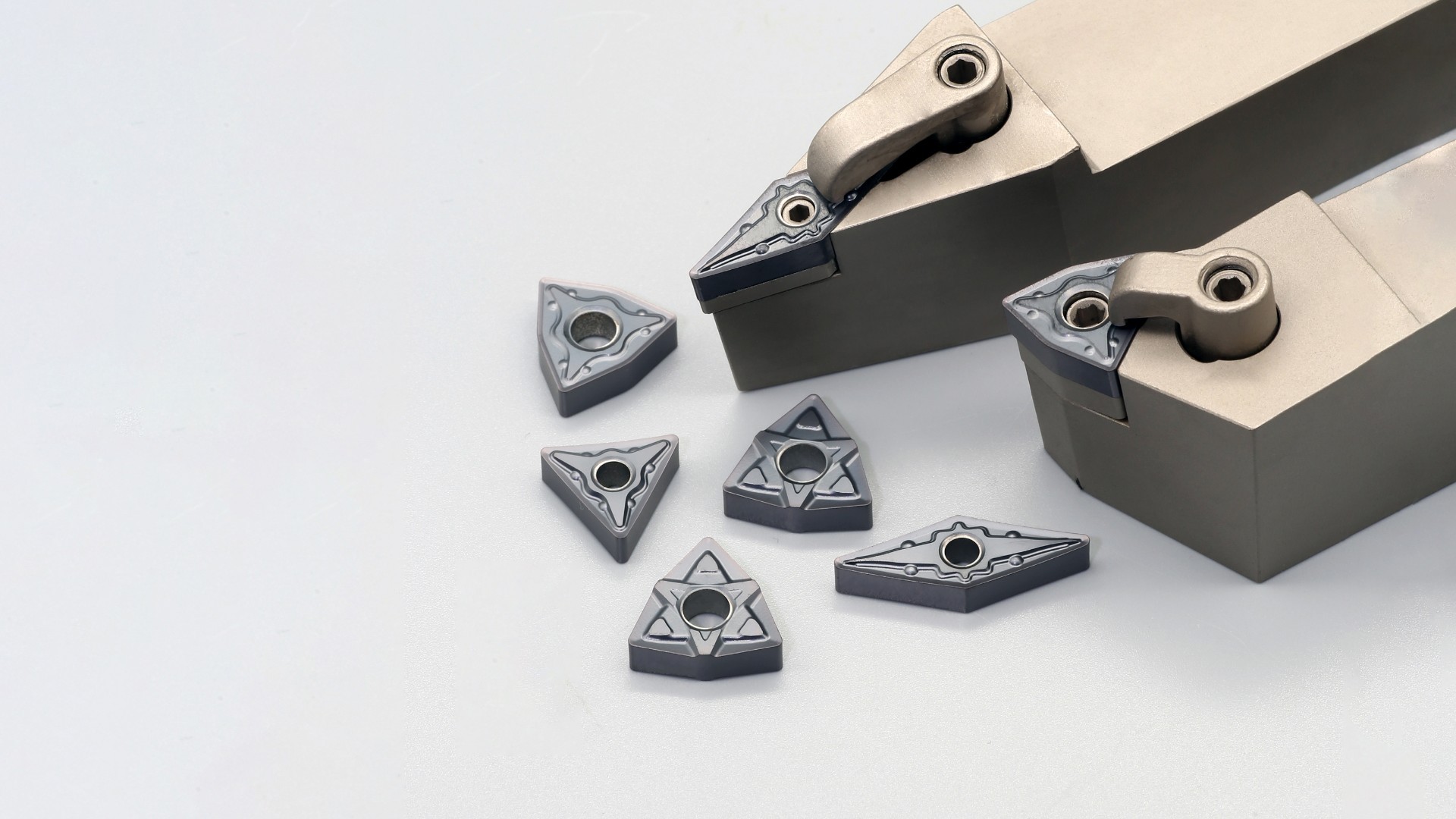

Introduction to Tungsten Carbide Cutting Blades

Tungsten carbide cutting blades are an essential tool for professionals and DIY enthusiasts alike. Known for their durability, sharpness, and precision, these blades enable users to achieve superior results in various applications, from woodworking to metalworking. At Dongcheng, we emphasize the importance of understanding how to effectively use these blades to enhance your craftsmanship and efficiency.

Understanding Tungsten Carbide

Tungsten carbide is a high-performance material that combines tungsten and carbon. This unique composition provides several advantages:

Increased Hardness: Tungsten carbide is significantly harder than steel, making it ideal for cutting applications.

Heat Resistance: It withstands high temperatures without losing its hardness, ensuring longevity.

Wear Resistance: The material resists wear and tear, allowing for prolonged use without frequent replacements.

Choosing the Right Tungsten Carbide Cutting Blade

Before diving into the usage techniques, selecting the appropriate blade for your specific project is crucial. Here are some factors to consider:

1. Blade Type

There are various types of tungsten carbide cutting blades, each designed for specific tasks:

Circular Blades: Ideal for cutting wood, plastic, and non-ferrous metals.

Reciprocating Blades: Best for demolition and rough cuts.

Jigsaw Blades: Perfect for intricate cuts and curves.

2. Tooth Configuration

The configuration of teeth on the blade affects the cutting performance:

Fine Tooth: Provides smoother cuts and is suitable for delicate materials.

Coarse Tooth: Removes material quickly and is ideal for rough cuts.

3. Size and Thickness

The size and thickness of the blade must align with the material being cut. Thicker blades offer more stability but may produce more heat, while thinner blades are more agile but can bend under pressure.

Preparing for Use

1. Safety First

Before using tungsten carbide cutting blades, ensure you are equipped with the right safety gear:

Safety Glasses: Protect your eyes from debris.

Gloves: Prevent cuts and improve grip.

Dust Mask: Avoid inhaling fine particles generated during cutting.

2. Inspect the Blade

Always inspect the blade for any signs of damage. A damaged blade can lead to poor cutting performance and increase the risk of accidents. Look for:

Chips or Cracks: Any visible damage can compromise the blade's integrity.

Dullness: A dull blade can cause excessive friction and heat, leading to premature wear.

3. Set Up Your Workspace

A well-organized workspace is essential for effective cutting. Ensure the following:

Stable Surface: Use a sturdy workbench or sawhorse.

Proper Lighting: Adequate lighting helps in making precise cuts.

Clamped Materials: Secure the material being cut to prevent movement.

Step-by-Step Guide to Using Tungsten Carbide Cutting Blades

Step 1: Mark Your Cut

Before starting the cutting process, clearly mark the cutting line on your material. Use a straight edge or a square for accuracy. This ensures that your cuts are precise and minimizes material waste.

Step 2: Adjust Your Tool Settings

Depending on the tool you are using, adjust the settings to match the material and blade type. For example:

Speed Settings: Higher speeds are typically better for softer materials, while lower speeds work well for harder materials.

Depth of Cut: Set the cutting depth according to the thickness of the material.

Step 3: Position the Blade

Carefully position the tungsten carbide cutting blade against the marked line. Ensure that the blade is perpendicular to the material for straight cuts. For angled cuts, adjust the angle accordingly.

Step 4: Start Cutting

With the blade in position, begin the cutting process. Here are a few tips to enhance your cutting technique:

Steady Pressure: Apply consistent pressure while cutting to maintain control.

Do Not Rush: Take your time to ensure accuracy and prevent the blade from binding.

Use a Guide: If available, use a guide to help maintain a straight line.

Step 5: Complete the Cut

Once you have finished cutting, carefully withdraw the blade from the material. Allow the blade to come to a complete stop before setting it down. This prevents accidents and ensures the longevity of the blade.

Step 6: Clean Up

After cutting, clean your workspace and the blade. Remove any debris or dust that may have accumulated. Proper maintenance extends the life of your tungsten carbide cutting blade.

Maintaining Tungsten Carbide Cutting Blades

1. Regular Cleaning

After each use, clean the blade with a soft brush or cloth to remove any residue. Avoid using abrasive materials that could scratch the surface.

2. Sharpening Techniques

While tungsten carbide blades are known for their durability, they will eventually dull. Use a diamond sharpening stone or a professional sharpening service to restore the edge.

3. Proper Storage

Store your blades in a dry, cool place away from direct sunlight. Using blade cases or holders can prevent damage and dulling.

Conclusion

Using tungsten carbide cutting blades effectively can significantly enhance your cutting experience, ensuring precision and durability in your projects. At Dongcheng, we are committed to providing high-quality tools and resources to help you achieve professional results. By following this step-by-step guide, you can master the art of using tungsten carbide cutting blades like a pro, leading to cleaner cuts, improved efficiency, and ultimately, superior craftsmanship. Embrace the power of tungsten carbide and elevate your projects to new heights.